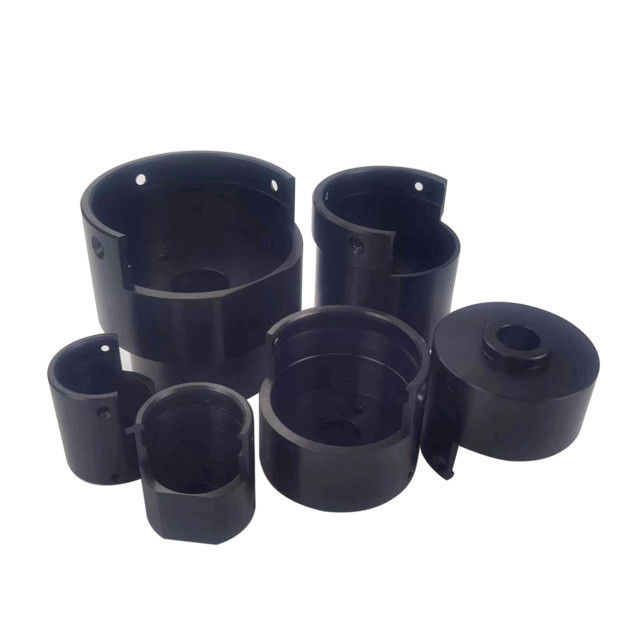

Reliable OEM CNC Machining Parts Supplier Durable Components for Diverse Industrial Applications

-

Highlight

Reliable OEM CNC Machining Parts

,OEM CNC Machining Parts Supplier

-

Product NameMachining Parts

-

Surface TreatmentAnodizing,polishing,chrome As Your Request

-

ServiceOEM /ODM

-

Apply ToAny OEM Cnc Machining Parts

-

SampleNeed To Pay Sample Fee

-

Tolerance0.01-0.005mm

-

ProcessCnc Machining+deburrs

-

FeatureDurable And High Precision

-

ColorCustomized Color

-

Delivery Time1~3 Days For Sample Order, 5-14 Days For Bulk Order After

-

Place of OriginShenzhen

-

Brand NameHS

-

CertificationISO9001:2015

-

Model NumberHS-488

-

Minimum Order Quantity1,Piece/Pieces

-

PriceUSD,0.59-28.89,Piece/Pieces

-

Packaging DetailsEPE foam inside and Carton outside or EPE foam inside and Wooden outside

-

Delivery Time3-14 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability5000,Piece/Pieces,Month

Reliable OEM CNC Machining Parts Supplier Durable Components for Diverse Industrial Applications

In today's advanced manufacturing world, companies rely on custom CNC machining services, machining and finishing, and trusted suppliers like CNC Machining, Inc. to produce high-quality precision parts.

|

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

|

|||

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|||

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|||

|

Titanium: Grade F1-F5

|

|||

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

|

|||

FAQ:

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 15 years of rich experience, covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings? Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.