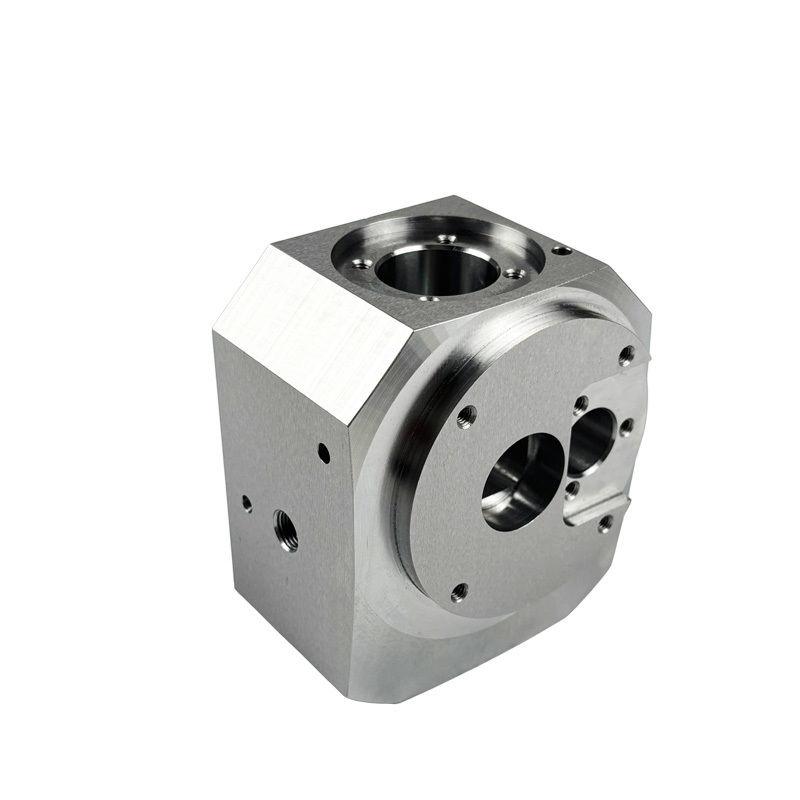

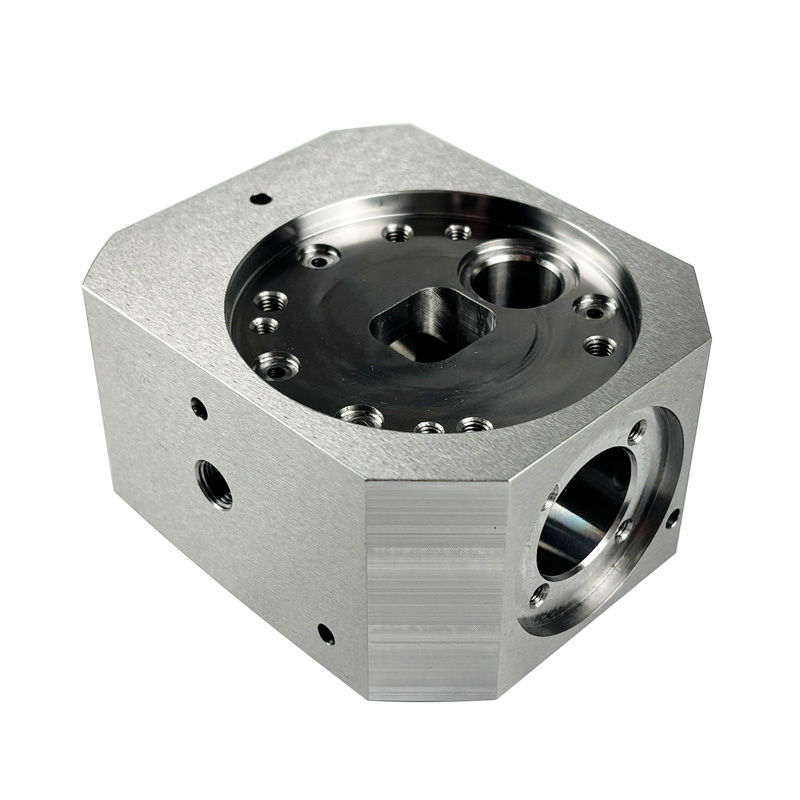

CNC machining and manufacturing of 1215 carbon steel metal parts.

-

Product NameMachining Parts

-

Surface TreatmentAnodizing,polishing,chrome As Your Request

-

ServiceOEM /ODM CNC Machining

-

Apply ToAny OEM Cnc Machining Parts

-

SampleNeed To Pay Sample Fee

-

Tolerance0.001-0.002mm

-

ProcessCnc Machining+deburrs

-

FeatureDurable And High Precision

-

ColorCustomized Color

-

Delivery Time3-5 Days For Sample Order, 10-15 Days For Bulk Order After

-

Place of OriginGuangdong

-

Brand NameHS

-

CertificationISO

-

Model NumberHS-45

-

Minimum Order Quantity1Piece/Pieces

-

PriceUSD,0.89-7.79,Piece/Pieces

-

Packaging DetailsEPE foam inside and Carton outside or EPE foam inside and Wooden outside

-

Delivery Time7-15 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability5000,Piece/Pieces,Month

CNC machining and manufacturing of 1215 carbon steel metal parts.

1215 carbon steel has become one of the most popular materials for CNC machined metal parts due to its superior machinability and cost-effectiveness. As a leader in CNC machining and fabrication, we specialize in transforming this free-cutting steel into precision components for a variety of industries.

|

Stainless Steel: SS201,SS301, SS303, SS304, SS316, SS416 etc.

|

|

Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc.

|

|

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

Copper: C11000,C12000,C12000 C36000 etc.

|

|

Iron: A36, 45#, 1213, 12L14, 1215 etc.

|

|

Plastic: ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc.

|

|

CNC Milling work range: 510 * 1020 * 500 mm(max) Tolerance: +/-0.01 mm

|

What is the CNC machining process?

You can optimize your design for computer numerical control (CNC) machining by following a few simple steps. Following design for manufacturing (DFM) principles will help you better utilize the diverse capabilities of CNC machining. However, this can be challenging due to the lack of unified standards within the industry.

CNC machining is a subtractive manufacturing technique. In CNC machining, various tools that rotate at high speeds (up to thousands of revolutions per minute) are used to remove material from a solid block to produce a part based on a CAD model. This type of machining is suitable for a variety of materials, including metals and plastics

CNC machined parts have high dimensional accuracy and tight tolerances, suitable for both mass production and one-off jobs. Compared to 3D printing, CNC machining is considered the most cost-effective way to produce metal prototypes.

What is 5-axis CNC machining?

Five-axis CNC machines are able to move the tool or part along five axes simultaneously, making it possible to manufacture parts with complex geometries. Multi-axis CNC machines provide an additional two rotational axes, thus eliminating the need for multiple machine setups and increasing machining efficiency.

What are the advantages and limitations of 5-axis CNC machining?

Five-axis CNC machining keeps the tool tangential to the cutting surface, allowing more complex and efficient tool paths. This machining method not only improves the surface finish of the part, but also reduces the machining time.

It is true that five-axis CNC machining has its limitations. Basic tool geometry and tool access restrictions still apply, for example, parts with internal geometry may not be machined. In addition, the cost of using such a system is generally higher.

![]()

![]()

FAQ:

Q: Are you a trading company or manufacturer?

A: We are a factory.

Q: How can I obtain a quotation?

A: To receive a quotation, please send us drawings in formats such as IGS, DWG, STEP, etc., along with a detailed PDF. If you have any specific requirements, please include them in the request, and we will provide professional advice for your reference.

Q: What if I don't have a drawing?

A: In such cases, you can provide us with samples or drawings. Rest assured, we will ensure the safety and confidentiality of any provided drawings.

Q: What is your delivery time?

A: Normally, it takes 7-14 days for the parts to be ready. We have systems in place to ensure timely delivery.

Q: How do you ship the products? What are the packing details?

A: For small quantity orders, we have partnerships with courier services like TNT, FEDEX, UPS, etc. For larger quantities, air or sea shipment options are available. We have standard packing details, but if you have any specific requirements, we are willing to assist you.

Q: Do you provide samples? Is there an extra charge?

A: Yes, we can provide samples, but there may be an extra charge for them.

Q: What are your payment terms? How can I make the payment?

A: Our payment terms are 50% T/T (bank transfer) in advance, with the balance payment due before shipment. If you have any other questions, please feel free to contact us.