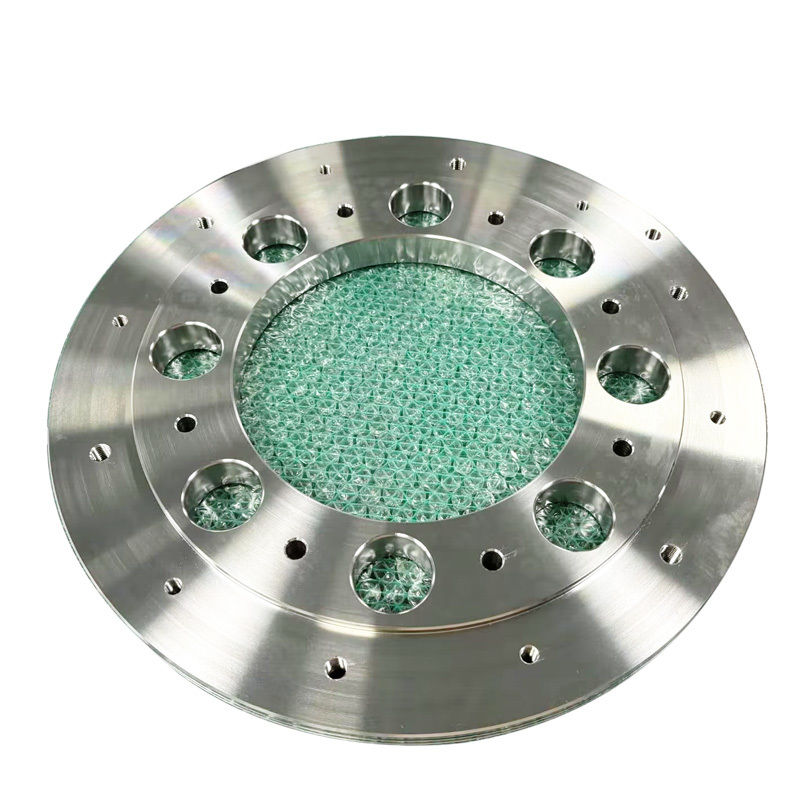

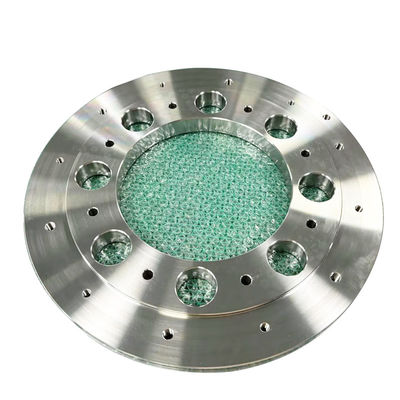

3-Axis Machining Services: Aerodynamic Machining and China Machining Solutions

-

Highlight

3-axis aerodynamic machining services

,CNC turning parts with warranty

,China precision machining solutions

-

Product NameMachining Parts

-

Surface TreatmentAnodizing,polishing,chrome As Your Request

-

ServiceOEM /ODM CNC Machining

-

Apply ToAny OEM Cnc Machining Parts

-

SampleNeed To Pay Sample Fee

-

Tolerance0.01~±0.005mm

-

ProcessCnc Machining+deburrs

-

FeatureDurable And High Precision

-

ColorCustomized Color

-

Delivery Time3-5 Days For Sample Order, 10-15 Days For Bulk Order After

-

Place of OriginGuangdong

-

Brand NameHS

-

CertificationISO9001,ISO14001

-

Model NumberHS-45

-

Minimum Order Quantity1Piece/Pieces

-

PriceUSD,0.89-10.79,Piece/Pieces

-

Packaging DetailsEPE foam inside and Carton outside or EPE foam inside and Wooden outside

-

Delivery Time7-15 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability5000,Piece/Pieces,Month

3-Axis Machining Services: Aerodynamic Machining and China Machining Solutions

Modern manufacturing relies on versatile three-axis machining services to achieve cost-effective production, relies on professional aerospace component pneumatic machining, and relies on competitive Chinese machining solutions to achieve global supply chains.

|

Stainless Steel: SS201,SS301, SS303, SS304, SS316, SS416 etc.

|

|

Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc.

|

|

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

|

|

Copper: C11000,C12000,C12000 C36000 etc.

|

|

Iron: A36, 45#, 1213, 12L14, 1215 etc.

|

|

Plastic: ABS, PC, PE, POM, Delrin, Nylon, PP,PEI, Peek etc.

|

|

CNC Milling work range: 510 * 1020 * 500 mm(max) Tolerance: +/-0.01 mm

|

Three-Axis CNC Machining A three-axis CNC machine tool, including lathes, milling machines, or machine centers, is capable of moving its tool (such as a cutter, drill, or milling cutter) along the X-axis (left to right), Y-axis (front to back), and Z-axis (up and down). Specifically, it can move horizontally (X-Y axes) and vertically (Z-axis) to control the depth of cut.

Three-Axis CNC Machining

A three-axis CNC machine tool (such as a lathe, milling machine, or machine center) moves its tool (cutting tool, drill, or milling cutter) along the X-axis (left to right), Y-axis (front to back), and Z-axis (up and down). Specifically, it can move horizontally (X-Y axis) and vertically (Z axis) to precisely control cutting depth. This flexibility makes three-axis machining adaptable to a wide range of complex machining needs.

This type of machine can cut and plane to a specific depth, depending on the tooling used and the material being processed. Because of its limited range of motion and inability to automatically rotate the workpiece, it's best suited for parts with simple shapes, designs, and minimal detail. These machines are particularly well-suited for manufacturing 2D and 2.5D parts, offering fast production times and reasonable costs, making them ideal for startups or small and medium-sized businesses.

Five-Axis CNC Machining

Five-axis CNC machines not only offer left-right, front-back, and up-and-down motion, but also can rotate the tool around two additional axes (A and B). This additional rotational capability enables machining at more complex angles and positions, accommodating more intricate part shapes and designs. Five-axis machining improves precision and efficiency, making it particularly suitable for producing parts with high detail and complex geometries.

With a full five-axis range of motion, these machines are capable of working at multiple angles, precisely manufacturing parts with smooth surfaces, complex angles, and contours. They also support continuous milling, significantly saving time and eliminating the need for manual intervention due to their ability to automatically rotate the workpiece. These high-tech CNC milling machines or routers are capable of manufacturing complex components such as turbine blades, molds, and impellers.

![]()

![]()

FAQ:

Q: Are you a trading company or manufacturer?

A: We are a factory.

Q: How can I obtain a quotation?

A: To receive a quotation, please send us drawings in formats such as IGS, DWG, STEP, etc., along with a detailed PDF. If you have any specific requirements, please include them in the request, and we will provide professional advice for your reference.

Q: What if I don't have a drawing?

A: In such cases, you can provide us with samples or drawings. Rest assured, we will ensure the safety and confidentiality of any provided drawings.

Q: What is your delivery time?

A: Normally, it takes 7-14 days for the parts to be ready. We have systems in place to ensure timely delivery.

Q: How do you ship the products? What are the packing details?

A: For small quantity orders, we have partnerships with courier services like TNT, FEDEX, UPS, etc. For larger quantities, air or sea shipment options are available. We have standard packing details, but if you have any specific requirements, we are willing to assist you.

Q: Do you provide samples? Is there an extra charge?

A: Yes, we can provide samples, but there may be an extra charge for them.

Q: What are your payment terms? How can I make the payment?

A: Our payment terms are 50% T/T (bank transfer) in advance, with the balance payment due before shipment. If you have any other questions, please feel free to contact us.