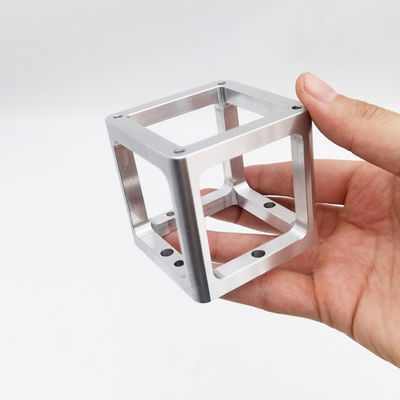

Reasonable Price Aluminium CNC Milling Parts Stainless Steel Brass Part CNC Turning Machining Parts

Machined parts description:

|

Custom CNC machining services

|

||||

|

Product Name

|

Custom CNC Milling Turning Machining Products

|

|||

|

Material

|

Metals: stainless steel, brass, copper, bronze, aluminium, aluminium alloy, steel, carbon steel, iron, environmental protection materials, etc.

Plastics: PU, PVC, POM, PMMA, peek,ABS, nylon, etc. |

|||

|

Product Size

|

According to drawing requirements

|

|||

|

Product color

|

According to drawing requirements

|

|||

|

Tolerance

|

(+/-0.001mm to +/-0.005mm)

|

|||

|

Surface treatment

of products |

passivation

Anodic oxidation Electroplating (zinc plating, nickel plating, chromium plating, tin plating, color, blue, white, etc.) Heat treatment knurling |

|||

|

Precision Machining

|

Turning, milling, drilling, grinding, wire cutting and so on.

|

|||

|

QC Inspection

|

The technicians inspect the production situation, the engineers on-site inspection, and the QC inspection after the completion of the product.

|

|||

|

Detection tool

|

Micrometer, wire gauge, caliper, needle gauge, altimeter, CMM.

|

|||

|

MOQ

|

1 (PCS)

|

|||

|

Sample

|

Free sanples

|

|||

|

Production capacity

|

5000 pieces per month

|

|||

|

Shipment

|

100% inspection before shipment (provide QC report)

|

|||

|

Our quality

|

Rich experience in manufacturing capacity, preferential prices.

|

|||

|

Company tenet

|

It's our job to help customers solve problems,

|

|||

|

Why choose us

|

With 13 years of CNC machining experience, we treat every customer carefully, we were rated as "shenzhen quality enterprise factory".

|

|||

![]()

FAQ:

Q3:Will Hongsinn sign Non-Disclosure Agreements (NDA)?

Yes. If it gives you peace-of-mind to sign an NDA, we are more than willing to do so. But we have the right to keep your design inconfidential no matter NDA is signed or not. All factories are camera monitored.

Q4:What is Hongsinn ‘s advantage?

1.13 years abundant experience.

2.Having professional technology and high accuracy prototypes

3.Top quality and competitive price.

4. Focus on customers’ need.

Q5:Why need make rapid prototype?

Prototypes allow the design team to test for functionality and ensure design and fit is correct. The prototypes can be used for sales meetings, customer presentations, and tradeshows overall time-to-market can be reduced since accuracy in design assures a streamlined project timeline.

Q6: Can we order samples for quality checking before placing an order?

Yes, we can offer you samples for quality checking first. But the freight is paid by you.

Q7: Can you provide OEM/ODM service?

Yes, we’re warmly welcome OEM orders. We accept OEM Logo & Package. For MOQ and price, please contact us.